89-400 PCR Black Ribbed Skirt Lid with Liner

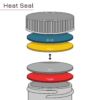

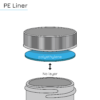

Also known as Ribbed Skirt Caps, This lid includes your choice of liner. (See Description Below about PS, and PS liners). The liner creates an airtight seal when used properly on the container. This PCR black ribbed skirt lid features a non-child-resistant polypropylene cap. In addition, it has a pre-inserted liner with an 89-400 neck size. It is great to enclose products safely with its airtight seal.

This Black Smooth Skirt Lid is made of 30% PCR polypropylene marked (PP). This helps keep your carbon footprint at ease, without having to worry about the final consumer choosing to compost the product. In addition, has a very good fatigue resistance and has an extremely high melting point. (320 degrees Fahrenheit or 160 degrees Celsius).

In conclusion, you can pair this PCR black ribbed skirt lid with liner with various Jars that match an 89-400 neck size. For instance, the first number represents the diameter of the container opening and in (mm). The second number represents the thread-depth of the closure’s skirt.

In other words, To help you in your product search. Pair this cap with one of our great “Matching Items” below and Read our Which Liner is Right for Me blog

Post-Consumer Recyclable Material (PCR)

What is Post-Consumer Recycled (PCR) Plastics?

Post-consumer recyclable plastics are often referred to as the acronym of PCR, which is material that is made from recycled products from consumers. These recycled items may vary from aluminum, paper, cardboard, and plastic bottles. These materials are usually put into production by local recycling programs and shipped to larger recycling facilities to be sorted categorically by material. These products are usually purchased in batches and then grounded (or melted) into small pellets and molded into new items. Once finished, the new PCR-made material can then be used in a variety of cases such as packaging for products.

What makes PCR Packaging different from Compostable and Recyclable Packaging?

PCR, Recyclable, and Compostable Packaging are all great items for sustainable packaging, they are each different in their own way from how they are made, and what they offer to consumers.

PCR Packaging is manufactured with a film that is made from recycled materials, and the percentage of the film depends on the use case. This makes PCR Packaging a less viable product to be recycled again since it is made from recycled products. This allows brands to meet their sustainability goals without having to worry about the consumer recycling the packaging after use.

Recyclable Packaging is categorized as recyclable when the materials used, can be processed and used again. Once the consumer chooses to put the product into the recycling process, it is grounded into raw materials and sold to manufacturers. The downside of recyclable packaging is that the benefits are dependent on the consumer making the choice to recycle their product, and having the knowledge of where to recycle.

Compostable Packaging is products that are broken down completely in a dedicated composting facility. Compost packaging has the benefit of not leaving any toxic residue when broken down. In order to be called compostable, the items must be able to biodegrade, break down into carbon dioxide, water or biomass at the same rate as cellulose (Material that makes paper). The downside of compostable packaging is that not all consumers have the knowledge of where to access an industrial composting facility.

Reviews

There are no reviews yet.