A Simple Guide to Estimating Injection Molding Costs

Ever since John Wesley Hyatt invented injection molding in the 1870s, thousands of companies have created millions of products through this fascinating technique. Injection molds let people make custom designs and products in a variety of materials, giving them the freedom to design things how they want.

But how much does it cost to get an injection mold? Read on for your guide to what you can expect to pay and some tips for estimating your injection molding cost!

Why Use Injection Molding?

Injection molding is great for producing large quantities of products at a low cost. Once you have the mold created for whatever you’re making, it’s very easy and cheap to keep producing copies of that same design over and over again.

The injection molding process lets you create strong, uniform products with minimal hassle. And injection molding is cheaper than many other types of manufacturing methods, all while giving you a quick turnaround time. It makes it easy to get your products in your hand as fast as possible for a low price!

There are lots of different injection materials you can use to fit your product’s needs, but thermoplastics are commonly used. This gives you plenty of choices for how you want to build your product and what kind of materials you want.

Estimating Your Costs

Your overall costs for injection molding can vary quite a lot. Unfortunately, this makes it a little difficult to give one specific number for what you can expect your costs to be.

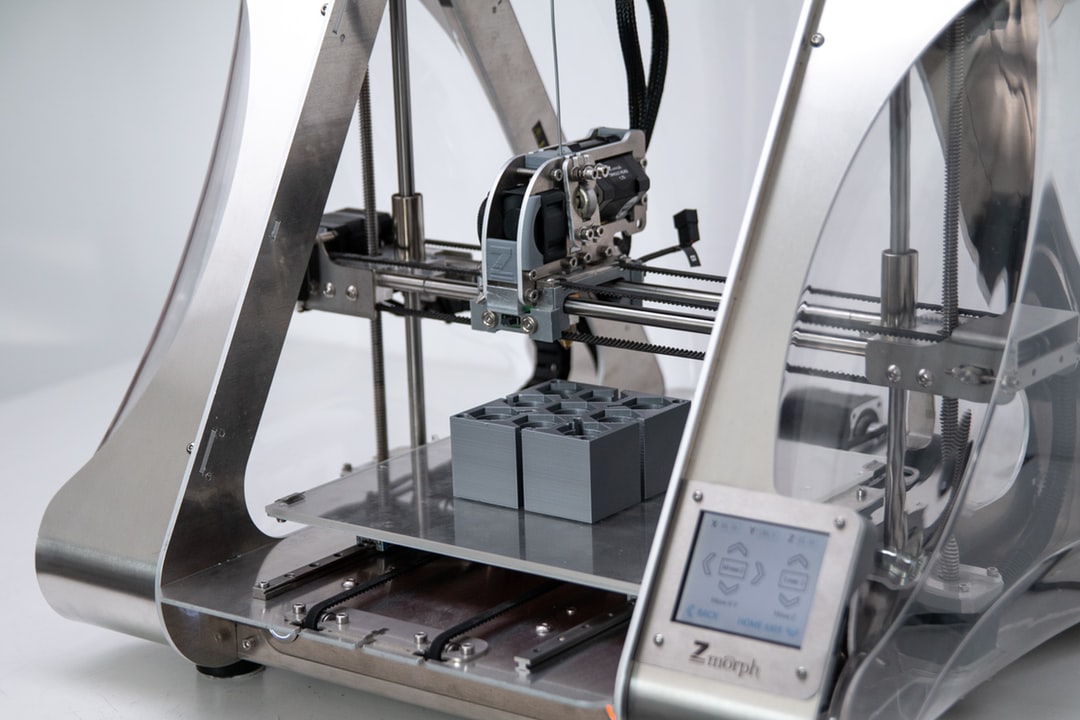

On the low end, you can pay as little as $100 for an inexpensive, low volume, 3D printed mold. This mold will do the job for a time, but you won’t be able to mass-produce a lot of products with it, as it will eventually wear out and break. It will also be of a lower quality, and your molded products may not have very fine details.

On the opposite end of the spectrum, you could expect to pay $100,000 or more for a high-quality steel mold designed for mass production. This will let you produce many more products at a much higher quality, but you will obviously have to pay more upfront for it.

One thing that you should always keep in mind is your eventual cost per part. While you may have very expensive payments upfront, if they go towards making millions of products, you’re still going to save money on each part.

Factors That Can Affect Your Costs

There are several factors that can affect your total injection molding costs. Depending on your job and needs, some of these may have a big influence on your costs, while others will barely even matter.

It helps to be able to look at the quoted prices for an injection molding service to find out exactly how much they charge for each aspect. However, here we give you a general breakdown to at least give you some idea of how much you can expect to pay.

Equipment Costs

This will affect you most if you decide to make your injection molds yourself. There are a lot of different levels of equipment that can make injection molds for your needs. The range of quality of these machines is one of the biggest cost differentials you’ll have to bear in mind when trying to estimate your costs.

A small desktop injection molding machine can help you with small quantities of supplies. These machines sit at a few thousand dollars each and are a great way to get your business started with injection molds without getting too pricey.

For industrial-scale projects, an injection molding machine starts at around $50,000 and goes up from there to hundreds of thousands of dollars. These machines will allow you to produce lots of products quickly but will require much more skilled labor and maintenance.

These high costs are one reason why so many businesses go with injection molding companies for their needs. These companies can produce molds and products quickly and efficiently while passing on savings to the grateful business that doesn’t need to buy an entire injection molding press for one part!

Tooling the Mold

If you decide to outsource your molding to another company, actually creating the mold for your products will be one of the biggest expenses you now face. There are a lot of ways of doing custom injection molding, and they all depend on what your end goals are.

For jobs where you only need a few parts and don’t want to pay much, 3D printing is a good choice for tooling your mold. Tooling a 3D printed mold can often cost you as little as a few hundred dollars for a single mold.

However, more complex machines like CNC or EDM machines can create much more complex and better molds. These will not only allow you to create more products but will make them much better as well. Tooling a mold with these methods will cost you at least a few thousand dollars, and can get up into the tens or even hundreds of thousands if you want the highest quality.

The Injection Materials

You also need to look at the type of materials you want to use. The material price per part tends to be approximately the same whether you’re going with a large batch or a small one. However, the type of plastic or other material you use can affect your total costs quite a bit.

Thermoplastics are among the most common materials for injection molding, and there are more than 100 different varieties you can use for your products. It’s also possible to inject metals or even ceramics in some situations! However, some of these materials can be more expensive to work with than regular plastic injection molding.

Labor and Time

When hiring an outside company to do your molding project, you’ll also have to factor in the labor and time costs involved. If you only need one mold and a few hundred parts made, you’re not going to pay very much for labor costs.

On the other hand, if you’re setting up an entire line of products and molds, you’re going to pay a lot more for labor. It’s important to figure out how many types and batches of products you need to help you get an idea of your labor costs moving forward.

Get Your Injection Molding Project Started Today

Injection molding is a great way to mass-produce your products at a low price while ensuring their uniformity. It’s definitely worth looking into, even if you only need to produce a small batch!

So if you’d like to learn more about injection molding, or you’re interested in getting a quote for your project, contact us! We’d be happy to help you in any way we can to ensure you get the product solutions you need.